AMD processors in ceramic packaging (top row), and in various colors of organic packages (bottom row)

AMD processors in ceramic packaging (top row), and in various colors of organic packages (bottom row)

Integrated Circuits (IC's), transistors, and computer chips come mounted in packages, which are encapsulated (hermetically sealed) to protect the internal chip's circuitry from physical damage and from moisture, dust and other types of contamination.

The IC package also helps with redistributing the Input & output of the chips circuitry to a more manageable component size for use by it's end customers, as well as providing a structure more adaptable to standardization, providing a thermal heat path away from the chip, providing protection from the possibility of errors due to alpha particles and other forms of radiation, and providing a structure that more easily allows electrical testing and burn-in by the chip's manufacturer.

The packages also make it easier to install the IC's in various types of equipment, since each package contains leads which can be either plugged into matching sockets or plugged into mounting frames. The IC package can also serve to interconnect multiple IC's both directly to each other using standard interconnection technologies such as wire bonding, and indirectly using interconnection pathways provided on the package such as those used in hybrid IC packages and multi-chip modules (MCMs).

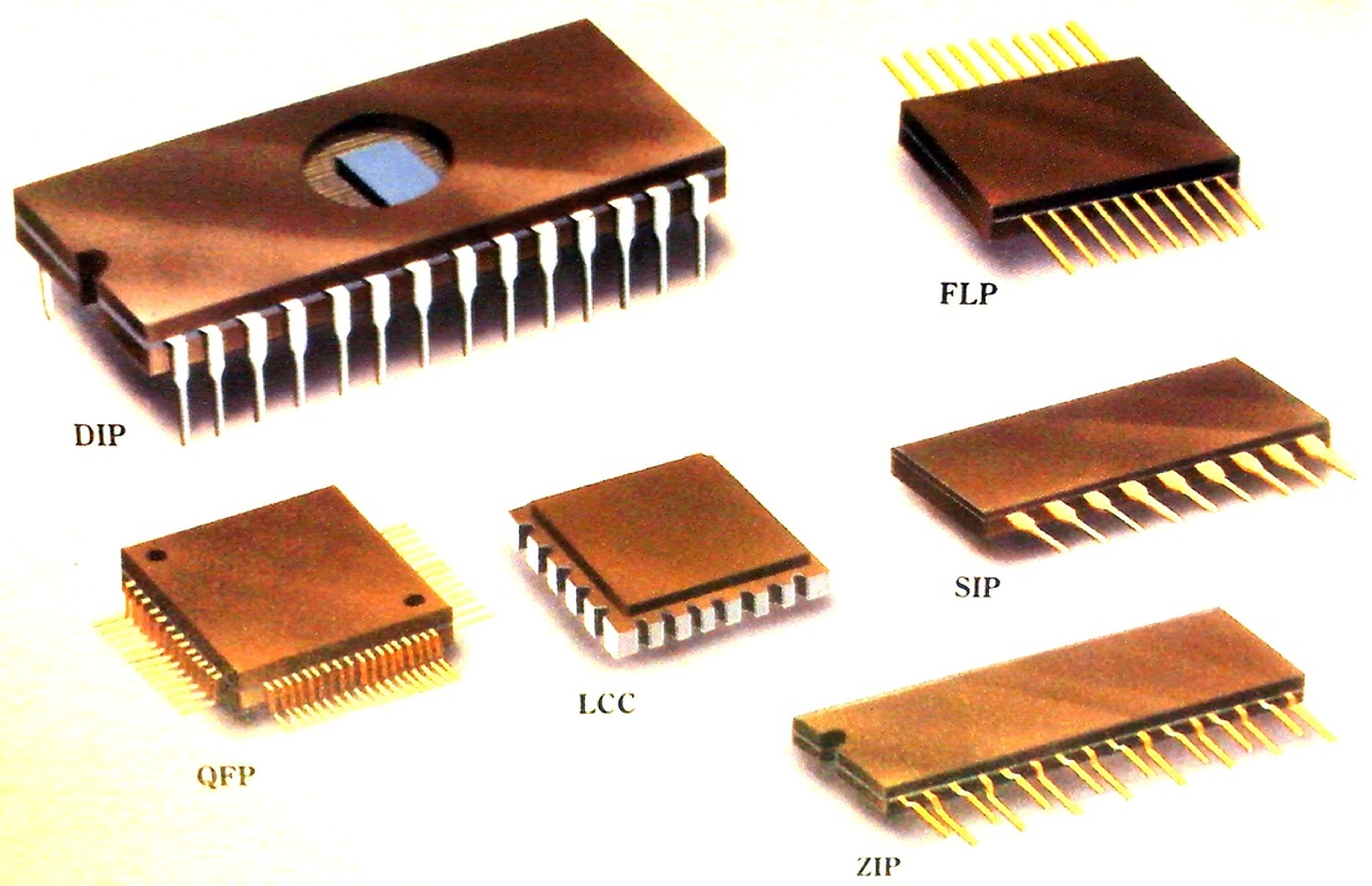

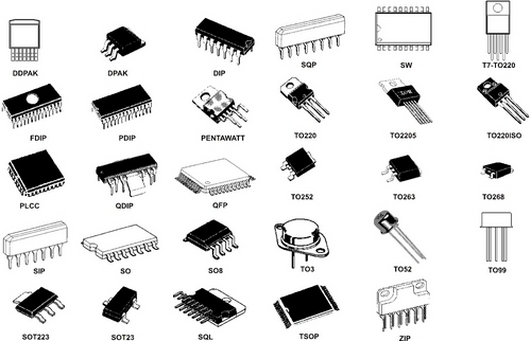

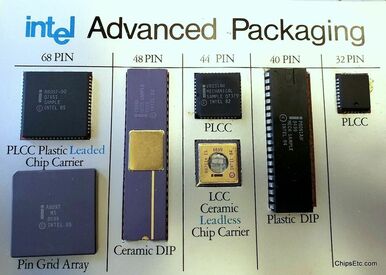

There are many different types of IC packages with each having it's own advantages and disadvantages. Another type of package is the Hybrid Integrated Circuit that contains numerous types of discrete and thick / thin film components and Integrate Circuits combined on one package.

Integrated Circuit package materials have evolved from metal cans, to ceramic, to molded plastic, to organic laminated substrates

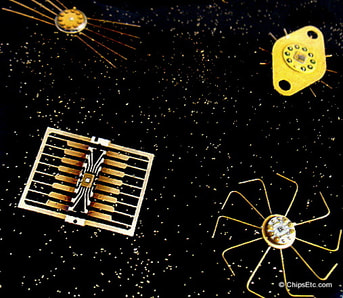

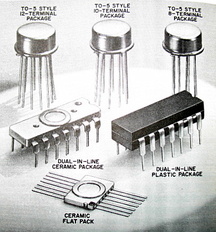

IC packages have been manufactured over the years using many different types of materials. Early discrete transistors were typically packaged within metal protective cans, some early IC chips were similarly also mounted inside metal cans with multiple wire leads.

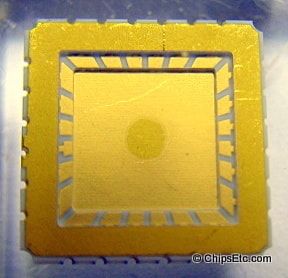

During the 1960s thru the 1990s most IC packages were made from either plastic (polymer resin), or ceramic. Ceramic packaging was more costlier, and heavier than plastic, but they were needed in high reliability military and aerospace applications due to their ability to handle high temperatures and extreme temperature fluctuations.

All early IC's throughout the 1960's will be found in ceramic packages - because they were originally being developed for primary use in military and space mission projects that were national priority needs at the time. IC's found in consumer products, such as televisions, would not start to be introduced until the early 1970s.

Ceramic packages from the 1980s and 90s are typically grey in color (some appear as purple), and earlier ceramic packages from the 1960s and 70s were white, with some early types known as "grey trace" or "zebra trace" that were white with visible grey traces leading from the chip to the leads.

By the mid 1990's, a cheaper, lighter, more reliable plastic packaging technology would be developed that could finally offer a replacement to ceramic packaging for high-reliability needs. Plastic chip packages are always black in color.

In 1998, Intel announced that it was ending it's long run of using Plastic PGA molded packages for it's consumer CPU's, replacing it with their new Organic Land Grid Array (OLGA) packaging.

The majority of all CPU and GPU packages on the consumer market today are organic, laminated substrate, packages with land grid array pads on the underside for interfacing the chip with the motherboard. Organic type packaging can typically be identified by it's green or brown color.

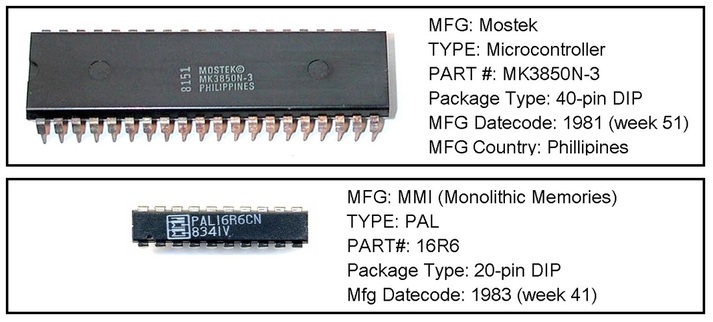

How to Identify the Manufacturer, Part # & Date of Integrated Circuits by manufactures markings:

Typical Integrated Circuit Identification from manufacture's marks found on package:

- Manufacturer's Name or Identifying Logo

- Part number

- Date of manufacture code:

(YYWW format: last 2 digits of year/2 digit Workweek)

(WWYY format: 2 digit Workweek/last 2 digits of year)

- Country of manufacture

You can Search Semiconductor Datasheets by IC Description or Part Number here:

|