Ford Motor Company gets into the chip manufacturing business

In 1982, Ford Motor company created a new subsidiary (Ford Microelectronics Inc.) to oversee research, development, design and manufacturing of their own Semiconductors for use in their production vehicles, and for aerospace applications for their other subsidiary, Ford Aerospace & Communications Corp. (producing satellites / defense products)

Ford Microelectronics was based in Colorado Springs, CO. They initially worked with silicon wafers for design and manufacturing of their custom integrated circuits. But in 1985, they would build a $33M factory to attempt to be one of the first companies to manufacture gallium arsenide semiconductor circuits in high-volume. Competing with Ford Microelectronics for the commercial gallium arsenide semiconductor market were Microwave Semiconductor (Siemens), Tachonics (Grumman), GigaBit Logic, and Vitesse Semiconductor.

Many had predicted that gallium arsenide semiconductors would replace silicon wafers because this promising technology offered faster performance and lower power requirements than silicon. Unfortunately, Ford Microelectronics, and most of their competitors, struggled with the high-costs of manufacturing gallium arsenide wafers, which were two to three times more expensive to produce than silicon wafers. Gallium arsenide wafers also turned out to be much more difficult to manufacturer than silicon wafers, largely due to the material's inherit brittleness. By 1990, GigaBit Logic, and Vitesse Semiconductor were the only companies that hadn't abandoned the gallium arsenide semiconductor market.

The Ford Microelectronics semiconductor manufacturing plant in Colorado Springs would eventually close in 1999. However, their integrated circuit design center would remain at this location. In 2000, Ford would split off it's automotive electronics design and manufacturing operations to Visteon Corporation (VC). (Similar to how Delco automotive electronics was split off from General Motors).

Ford Motor Company would also partner with Intel, Motorola, and Toshiba for supplying them with various Microcontroller and Microprocessor chips for their engine control units through out the 1980s and 90s.

Ford early Automotive Electronics - Thin-Film Hybrid Integrated Circuit (late 1970s)

Item #984

Clear Lucite paperweight from Ford has a Thin Film Hybrid Integrated Circuit embedded inside.

Reads "Ford - Leading the way in vehicle electronics. Vehicle and Engine controls - instrumentation - Entertainment".

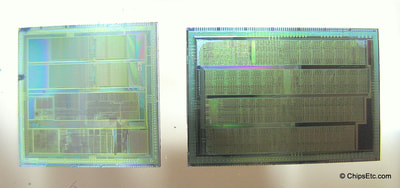

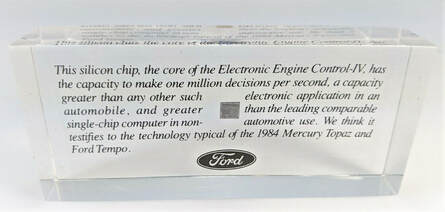

Ford Automotive Electronics - Engine Control IV Integrated Circuit chip (1984)

Sold

Clear Lucite paperweight from Ford has a custom 16-bit Intel 8061 microcontroller chip embedded inside that was used in their Electronic Engine Control IV automotive computer.

Reads "The silicon chip, the core of the Electronic Engine Control - IV, has the capacity to make one million decisions per second, a capacity greater than any other such electronic application in an automobile, and greater than the leading comparable single-chip computer in non-automotive use. We think it testifies to the technology typical of the 1984 Mercury Topaz and Ford Tempo."

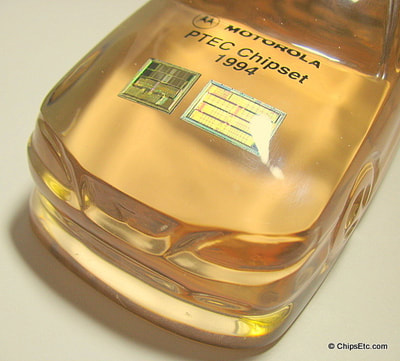

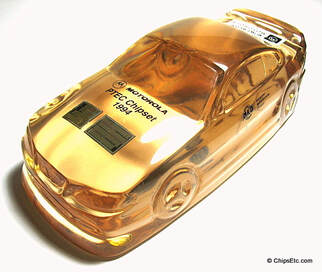

Ford Mustang PTEC Automotive Powertrain Management Chips (1994)

Item #968

This Acrylic paperweight, resembling a Ford Mustang, contains the two Motorola PTEC Automotive engine power management chips that were designed and manufactured by Motorola for use in Ford Motor Company automobiles starting in 1994.

Ford replaced the Intel designed EEC IV microcontroller used in their engine management systems since 1983, with the new Motorola based PTEC microcontroller systems.

Ford's PTEC powertrain microcontroller system used two computer chips, a 32-bit RISC based Motorola PowerPC microprocessor chip, and 28K of RAM memory.